System Overview:

The intelligent warehouse management system based on RFID technology is to add RFID terminal equipment and electronic tags to the traditional warehouse management work methods and processes to achieve data collection and complete the job management in the warehouse. From the core process of warehouse management: storage-in-warehouse operations-out-warehousing-return and inventory control to achieve more efficient and accurate management. Effectively control and track the whole process of logistics and cost management of the warehouse business, and achieve perfect enterprise storage information management.

RFID technology has the characteristics of long reading distance, fast reading speed, batch group reading, not easy to be defaced, and large data capacity. It can effectively simplify the complicated operation process of the warehouse and improve the efficiency and transparency of enterprise information management. At the same time, the system integrates a variety of hardware solutions to meet different application needs of users, through the use of different technical means to achieve effective process improvement and improve work efficiency. To meet the information, intelligence, and modernization requirements of the final enterprises and organizations, and help customers start a smart transformation.

system introduction:

RFID is a non-contact automatic identification technology. Its basic principle is to use radio frequency signals and spatial coupling (inductive or electromagnetic coupling) non-contact transmission characteristics to achieve automatic identification of the identified objects and exchange data. The system adopts B/S+C/S structure, which is composed of data traceability platform (B/S) and handheld (PC) client program (C/S). The data traceability platform has the functions of management and enterprise ERP system data docking, client data interface support, and traceability information viewing. The client program is divided into two types according to the software usage environment: handheld client (winCE system) and PC (window system) client. The handheld client has functions such as receiving, loading, picking, and counting, and the PC client has functions such as label initialization and delivery.

System network structure:

System goals:

² The space of the warehouse is limited, and one cargo location corresponds to multiple SKUs, which improves the warehouse utilization rate.

² The periodic picking volume is large, and there are many urgent orders. It is necessary to improve the picking efficiency and optimize the picking path.

² Improve the efficiency of receipt and delivery, the accuracy rate of receipt and delivery is 100%.

² To ensure the accuracy rate of the goods in the warehouse and improve the inventory efficiency.

² Anti-counterfeiting tracing: used for online anti-counterfeiting and product flow tracking.

² Improve the information management of brand warehouses and optimize the logistics supply chain of finished products.

System functions:

1) RFID tag initialization and supply method

Rovinj will provide the final RIFD label products after sorted printing, initialization, testing and sorting packaging.

After initializing the RFID tags according to the production order, the brand distributes them to the corresponding processing manufacturers.

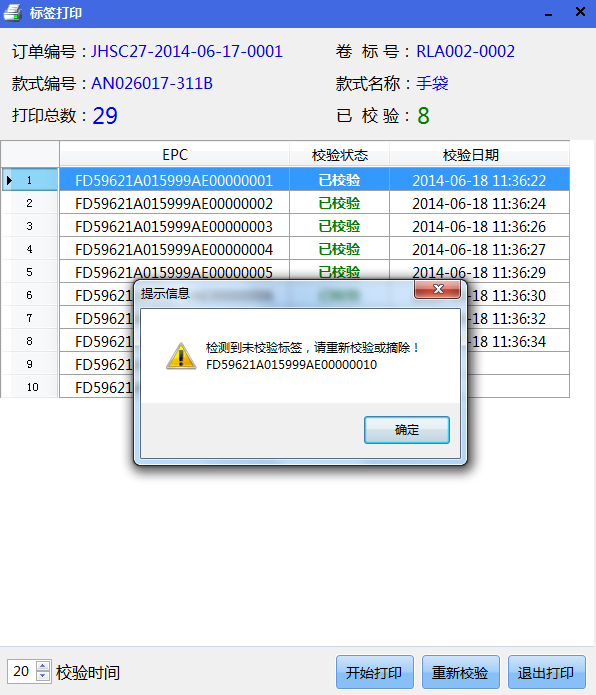

2) Processing factory inspection and packing

After the production is completed and before packing and delivery, the processing factory uses the RFID labeling machine and RFID scanning packing system provided by Rovinj to carry out RFID tag detection. Check the products before leaving the factory to minimize the subsequent problems caused by the wrong label or forgetting to hang the label in the processing link.

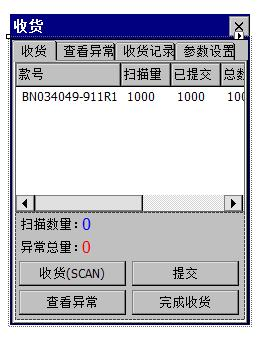

3) Storage management

When the warehouse receives the goods from the processing factory, it uses RFID handheld machines to perform unopened scanning and verification of the goods, and uses the ERP system's warehouse receipt as the source bill to quickly and accurately receive the goods.

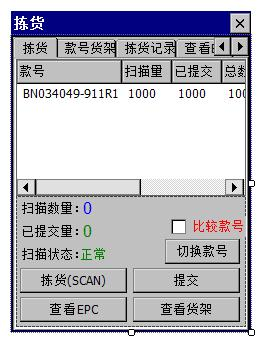

4) Homework

Commodity shelves: computer calculation automatically allocates the cargo space, and the warehouse staff shelves according to the instructions.

After the standard-based shelving operation, the system automatically finds the storage position of the commodity, and through computer calculation, guides the picking path according to the stored position of the single commodity, optimizes the picking path, and picks in the least time Goods operation. Simple and intuitive picking instructions, even new employees who have just joined the job can easily complete the work.

5) Outbound management

Using the RFID desktop all-in-one machine, the ERP system invoice is used as the source bill to quickly and accurately scan the shipment. If it is found to be inconsistent with the invoice SKU or quantity, the system will prompt an exception, only after the exception information is eliminated Complete the operation.

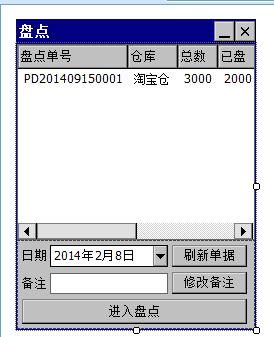

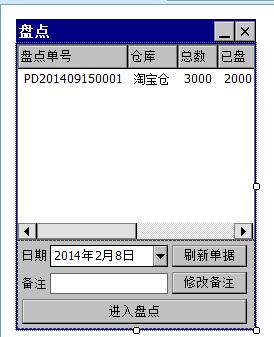

6) Warehouse inventory

Use RFID handset to operate. The inventory system supports functions such as blind inventory, single inventory, single inventory, and stock search.

When performing partial or full inventory of the inventory in the distribution center, RFID handheld devices are used. The operator uses a handheld device to scan one by one the area shelves that need to be counted, and the detailed varieties and quantities of the batch of goods are counted in real time. After the actual scan results are combined and statistically

uploaded to the traceability platform, the traceability platform will check the inventory data.

When you need to find a specified variety of goods without knowing the specific location of the goods, you can do it with an RFID handheld.

l Enter the color code of the goods to be found on the handheld

l Use the handheld to perform overlay scanning.

l When approaching the goods to be found, the hand-held machine will issue a warning sound. The closer to the goods, the louder the sound will be, thereby helping the personnel to find the goods accurately.

RFID data traceability platform

The RFID data tracing platform is aimed at all the above modules with data display modules, and also includes: user management, basic data management, anti-counterfeiting tracing modules.

Data docking platform

The project uses the API interface for data exchange, and pulls the required documents from the ERP as the system's source documents. If necessary, the data of this system can also be backfilled into the ERP system.

In the entire RFID warehouse management operation, the characteristics of RFID technology such as long-distance identification, large-volume reading and accuracy are applied to the storage management, warehouse operations, warehouse operations, inventory, inventory, sorting and other processes. Using the characteristics of RFID, the traditional inventory management method is changed. The intelligently collected data is analyzed and processed to gain smart insights to improve the leanness of the business, and can maximize the investment value of the enterprise, save human resources, and bring a new brand to the enterprise. Warehouse management.

.png)

Product

Solution

Product