· Industry Painpoints

◆ Low Efficiency:

Manual picking and inventory is too low efficiency and accuracy.

Barcode has to be scanned one by one.

RFID handheld scanner will easily cause miss scanning or scanning extra tags.

◆ Wrong Packing:

It is easy to pack more or less or wrong products during the packing step. The packing accuracy problem will lead to the decline of factory KPI.

◆ Wrong Tagging:

Tagging a wrong label

Miss tagging or extra tagging

◆ Tag Error:

It is hard to detect the error tags, such as the damaged labels and tag code writing failure.

· How does our solution work?

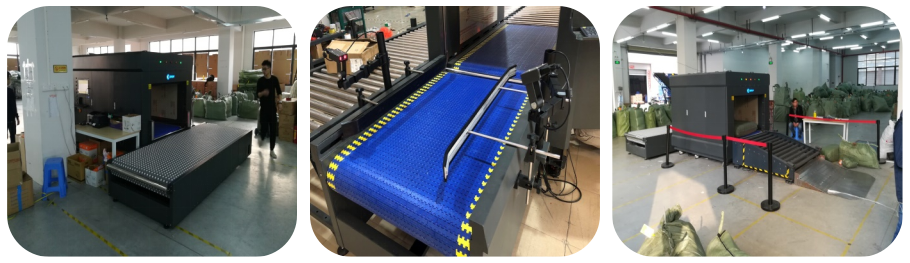

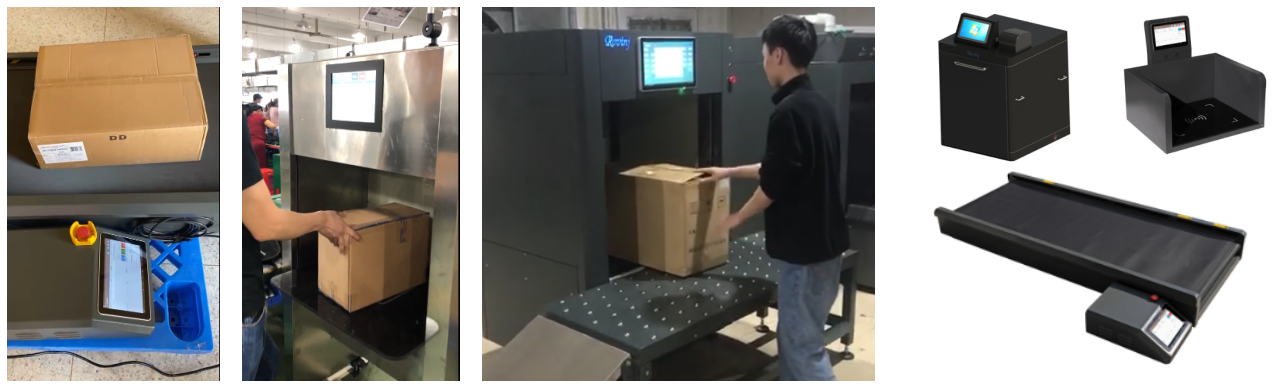

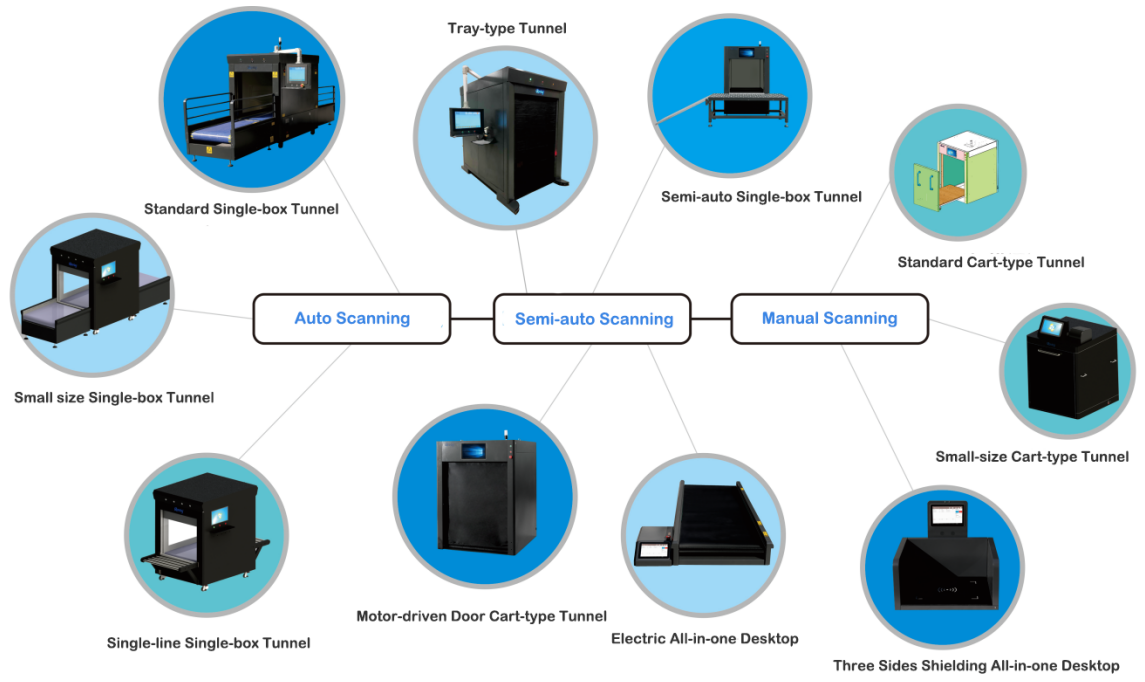

◆ RFID Fast Scanning Tunnel Machine:

Integrated with RFID technology, the ROV-SC201 single box tunnel machine can finish scanning 600+ products in 3 seconds, without unpacking the cartons. We just need to put the cartons on the front conveyor, and then the carton will enter the middle machine. The tunnel will scan the RFID tags inside the carton. With multi sensors, shielding doors and auto controll, the RFID tunnel perfectly solves the problems of miss scanning or scanning extra tags, truly realizes single grade management.

◆ RFID Fast Scanning Tunnel Machine - Larger Size:

ROV-SC401 tray type tunnel machine is perfectly suitable for larger size products or multi cartons scanning. Just put all the goods on a pallet or in a trolley, and then put it into the tunnel with forklift. Then the tunnel will fast finish scanning all the RFID tags inside.

◆ RFID Fast Scanning Tunnel Machine - Smaller Size:

Considering to the site area limitation, there are some smaller size tunnels or all-in-one readers, which are suitable for smaller warehouses or smaller amount scanning.

· Industry Value

| Factory | Brand |

| ① Effectively avoid the problems such as wrong tagging, quantity abnormal, etc. ② Improve customer satisfaction and increase orders. ③ Reduce the loss of profits caused by label error, and realizes win-win cooperation between the factory and the brand. | ① The RFID label abnormity problem is solved from the production side, which greatly reduces the loss and cost of goods returned and reworked. ② Reduce the on-site QC times, which helps lower the labor cost for business trip. ③ Realize data exchange, more accurately know about the production and delivery progress of the factory, and facilitate the enterprise to formulate business plans. |

· Product Series

Wake up Intelligent Management, Start up the Journey with Rovinj

Click to View More Details

View DetailsMedical

Consumables

Warehouse

Oversea

.png)

Product

Solution

Product