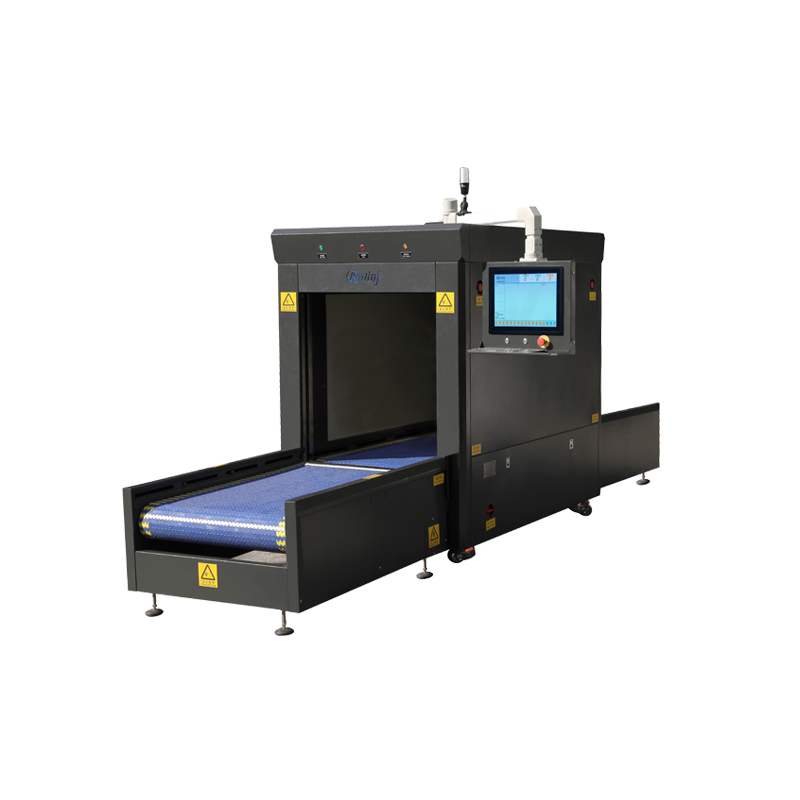

| Product Name:RFID Single-Box Tunnel Machine | Model:ROV-SC201 | Material:Spray-paint Carbon Steel |

| Weight:About 550KG | Size:1120 (width) × 4100 (depth) × 1900 (height) (The width of the lifting arm is not calculated) | Working Frequency:902.75MHz~927.25MHz |

The ROV-SC201 series is an industrial-grade RFID acquisition tunnel, which is independently designed and developed by our company. It takes Radio Frequency Identification Technology as the core and combines mechanical design, multiple sensors, electromagnetic shielding, automated control and other technologies. It completely solves the problems such as tag miss-reading or reading the wrong tag in the supply chain, meeting the requirement of high efficiency and accuracy of product circulation. What’s more, the tunnel combines the warehouse management system to completely overcome the shortcomings of barcode management, truly realizing the SKU automated management. And it also saves labor costs and greatly improves work efficiency.

Industry Application: The tunnel is mainly used for SKU identification, such as warehouse management of fashion, leather goods and luggage, alcohol, electric power, the comparison of SKU tag and box label, product inventory, etc.

n High identification efficiency: It can read 600+pcs of tags at a time within 3 seconds;

n Professional motion control and mechanical design fully solves the problem of tag miss-reading ;

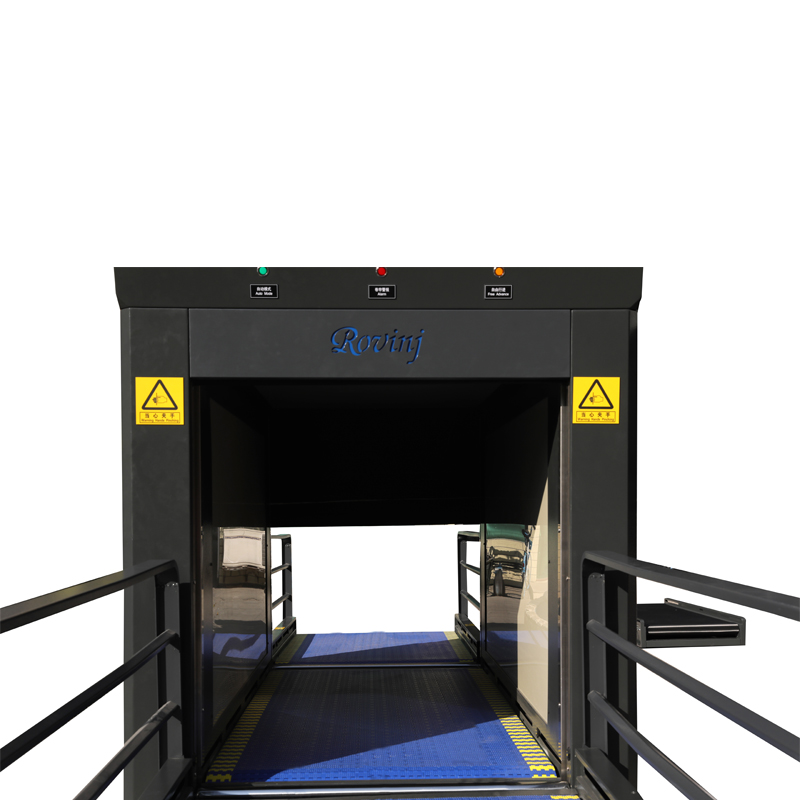

n Compact electromagnetic shielding and radio frequency optimization can eliminate the harm of RF radiation to the human body, and the tag reading accuracy reaches 100% (Depends on the reading environment and performance of tags);

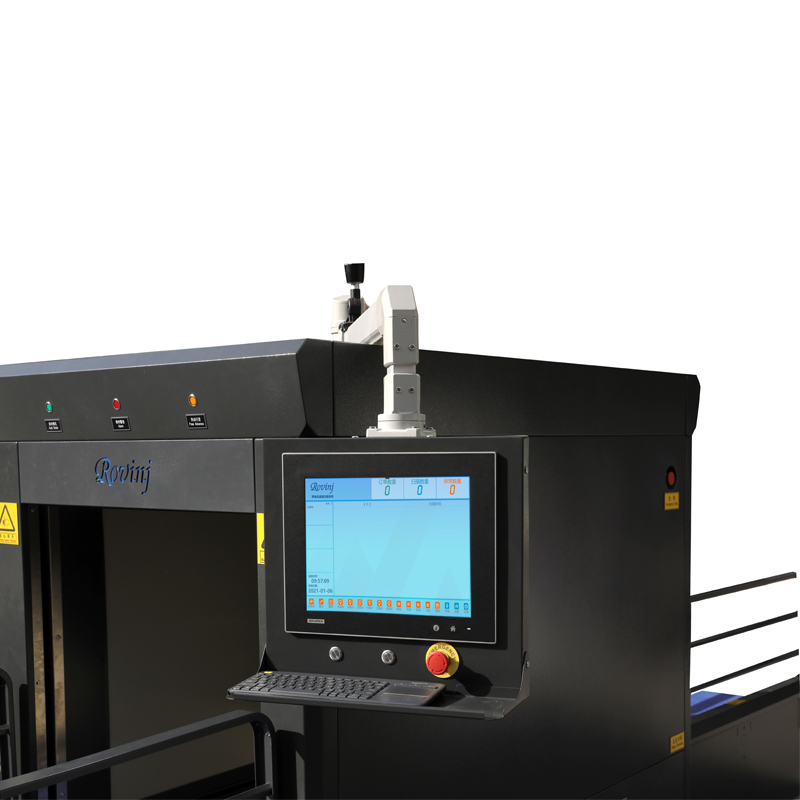

n The industrial computer software can control the function of the whole machine and monitor the running status. There are also external mechanical buttons, which are convenient for the operators to control the working status of the equipment at any time;

n The design of industrial plastic mesh port conveyor line fully solves the belt offset maintenance problem;

n There is maintenance door on both sides, which facilitates the equipment maintenance;

n Optional sorting module for abnormal boxes/goods/items meets the needs of different users. And we support customers to develop secondary software.

Main Specifications | |

Air Interface Protocol | EPC Global Class1 Gen2/ISO 18000-6C |

RFID Frequency | 902MHz~928MHz |

RFID Frequency Mode | Fixed Frequency / Frequency Hopping, 10 Frequency Hopping Points |

Reader Output Power | 5-32.5±0.5dBm |

Conveyor Speed | Up to 40m/min |

Conveyor Load Bearing | Up to 80KG |

Efficiency | 8~10boxes/min |

Number of Tag Reading | 600+pcs |

Reader | Imported (Impinj-R420) |

Reading Efficiency | Within 3 seconds |

Reading Mode | Motion/Motionless |

Operating Mode | Interval T cycle / Continuous operation / External trigger |

Screen | 18.5-inch Resistive Touch (Embedded) |

Industrial Computer | I5/4GB |

Automatic Conveyor Belt | Three Conveyors/ Independent Power Control |

Material of Conveyor Belt | Industrial Chain Plate Belt |

Programmable Controller | Imported |

Electronic Control System | Original PLC |

Antenna | 4 Groups of 9dbi Antennas |

Photoelectric Switch | 8 Groups/Imported |

Load Capacity | 80kg |

Adjustable Speed of Conveyor | 0—40m/min |

Reversible or not | Reversible Conveyor |

Opening Speed | 1 second |

Dock With Production Line or Not | Yes |

Physical Environment | |

Model Code | ROV-SC201 |

Total Size (mm) | 1120 (width) × 4100 (depth) × 1900 (height) (The width of the lifting arm is not calculated) |

Inner size(mm) | 800 (width) × 1600 (depth) × 880 (height) |

Front/Rear Conveyor Size (mm) | 960 (width) × 1200 (depth) × 580 (height) |

Maximum Passable Size of Box (mm) | 790 (width) × 1100 (depth) × 800 (height) |

Weighing Module | Optional |

Sorting Module | Optional |

Total Weight | About 700KG |

Operating Temperature | -20℃– 60℃ |

Storage Temperature | -10℃~60℃ |

Operating Humidity | 20 – 95% (non-condensing) |

Work Voltage | 220VAC(±10%)50±3HZ |

Power | 1000W |

Enclosure Material | Spray-paint Carbon Steel |

Shielding Performance | 5-10CM |

Wake up Intelligent Management, Start up the Journey with Rovinj

Click to View More Details

View DetailsMedical

Consumables

Warehouse

Oversea

.png)

Product

Solution

Product